Ensure Precision and Reliability with Membrane Switch for Better Control

Ensure Precision and Reliability with Membrane Switch for Better Control

Blog Article

Discover the Versatile Uses of Membrane Switch Over in Modern Electronic Devices

In the realm of modern electronics, the application of membrane layer buttons is extremely considerable, covering from smooth consumer gizmos to important medical devices. These slim, versatile interfaces not only improve tool operation with their responsive responsiveness however additionally considerably improve durability by standing up to ecological risks like dampness and dust. As industries proceed to develop, the integration of membrane layer switches in devices design is crucial, appealing not just to satisfy but go beyond the rigorous needs of both functionality and visual charm. Discover more concerning exactly how these parts are forming the future of technology.

Discovering the Function of Membrane Changes in Consumer Electronics

Why are membrane switches over so common in customer electronics? The solution exists in their distinct mix of reliability, flexibility, and price. Membrane switches are cost-efficient to make, making them an attractive choice for high-volume manufacturing typical in consumer electronics. Their building, including a slim, adaptable layer that can easily be integrated into different gadgets, permits streamlined, compact product layouts.

Furthermore, these switches are understood for their longevity and reduced upkeep. From microwave ovens to remote controls, membrane buttons offer a practical, user-friendly user interface that supports the vibrant nature of consumer electronic devices.

Membrane Switches Over in Medical Tools: Enhancing Interface

Membrane buttons likewise play a significant duty in the realm of clinical devices, where they boost user interfaces with their distinctive advantages. These buttons are especially valued for their reliability and simplicity of sanitation, vital in health care settings where tidiness is extremely important. The smooth, sealed surface of membrane layer switches enables very easy disinfection, decreasing the risk of contamination and spread of microorganisms. Furthermore, their layout flexibility fits the aesthetic and ergonomic requirements of clinical equipment, making gadgets extra user-friendly and accessible for health care specialists.

Membrane switches also add to the sturdiness of medical devices. Their resistance to contaminants and fluids makes certain that essential tools stays operational in different medical settings, consisting of surgeries where direct exposure to liquids prevails. This longevity, paired with responsive comments and low-profile layout, makes membrane switches over an essential element in improving the efficiency and safety of clinical gadget interfaces.

The Impact of Membrane Layer Activates Industrial Equipment Design

In the world of industrial devices layout, the unification of membrane buttons has noted a substantial development. These buttons have actually changed how manufacturers come close to interface functionalities, using a blend of longevity and adaptability that is important in rough environments. The slim profile of membrane layer switches permits more small machine styles, while their resistance to dirt, water, and chemical contaminants makes them ideal for industrial settings. This adaptability has assisted in the growth of tools that is not just more robust however likewise much easier to keep and tidy, thereby decreasing downtime and operational expenses.

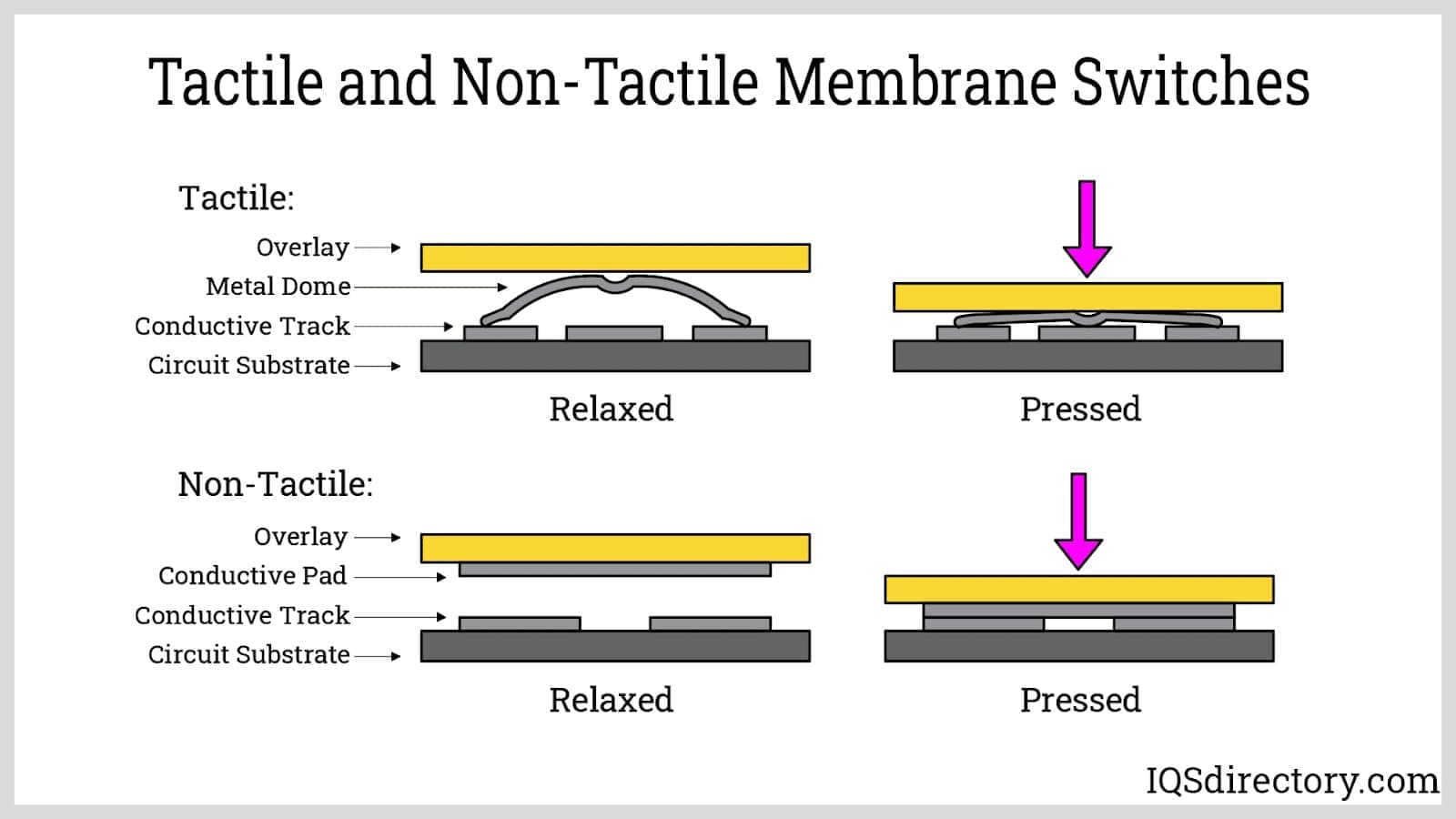

Moreover, the customizability of membrane layer changes allows designers to integrate specific tactile responses and visual overlays that boost the individual experience and boost efficiency. This integration supports drivers in attaining accuracy control over complicated machinery. The general impact is a significant enhancement in the capability, integrity, and reference user-friendliness of commercial devices, lining up with the increasing needs for technical advancement and functional effectiveness in contemporary industries.

Verdict

Membrane layer switches have actually revolutionized contemporary electronics, using streamlined, resilient, and personalized user interfaces across different fields. This technology not only fulfills the demanding problems of various areas but likewise dramatically improves individual experience, making membrane layer switches over a cornerstone of contemporary electronic style.

In the world of modern-day electronics, the application of membrane switches is incredibly considerable, extending from sleek consumer devices to essential medical devices.Why are membrane layer switches so common in consumer electronic devices? Membrane layer buttons are cost-efficient to manufacture, making them an attractive choice for high-volume production normal in customer electronic devices. From like it microwave stoves to remote controls, membrane switches offer a functional, straightforward user interface that sustains the vibrant nature of customer electronics.

Report this page